FOAM FOR SEARCHING DEFECTS IN UNITS OF NPP, TPP

We bring to your attention Foaming agent for searching for defects in units of nuclear power plants, thermal power plants

To date, when the power unit is operating at capacity, the following methods are used to search for suction cups in the pipe systems of turbine condensers of NPPs, TPPs:

- 1. Candle flame.

- 2. Halogen leak detectors.

- 3. Ultrasonic leak detectors.

- 4. Application of various types of polyethylene films.

- 5. «Aroma Ukraine» LLC offers a completely new approach to solving the problem of finding cooling water suction in the steam part of heat exchange equipment using the «FORWARD Modernized» foam concentrate

«Aroma Ukraine» LLC offers a completely new approach to solving the problem of finding cooling water suction in the steam part of heat exchange equipment using the «FORWARD Modernized» foam concentrate

«Aroma Ukraine» LLC has been working in the field related to the production of foam concentrates for industrial use for many years. The special formula of the «FORWARD Modernized» foaming agent, developed by the leading specialists of «Aroma Ukraine» LLC, allows the use of foam in conditions of high humidity and ambient temperature in the water space of turbine condensers.

Brief description of the method:

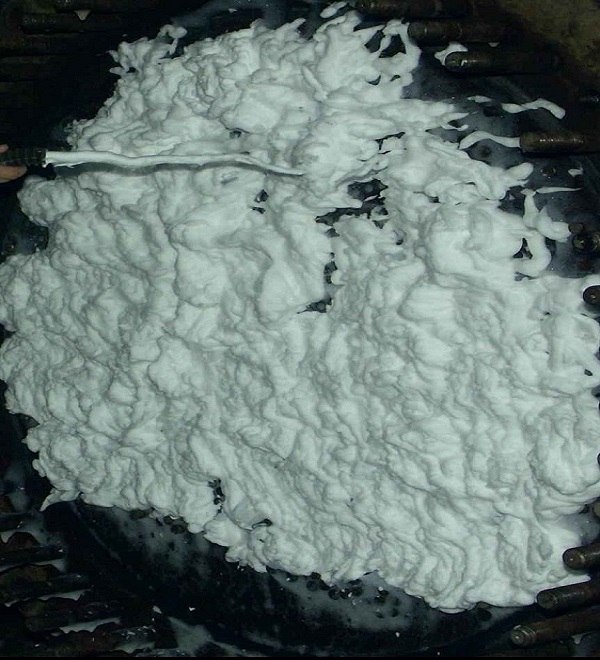

- 1. Foam, simultaneously from both sides of the heat exchanger, using a special foam generator, is applied to the surface of the tube sheets (Fig. 1, 2).

- 2. Using spatulas, the foam is evenly smoothed over the surface of the heat exchanger tube sheets (Fig. 3).

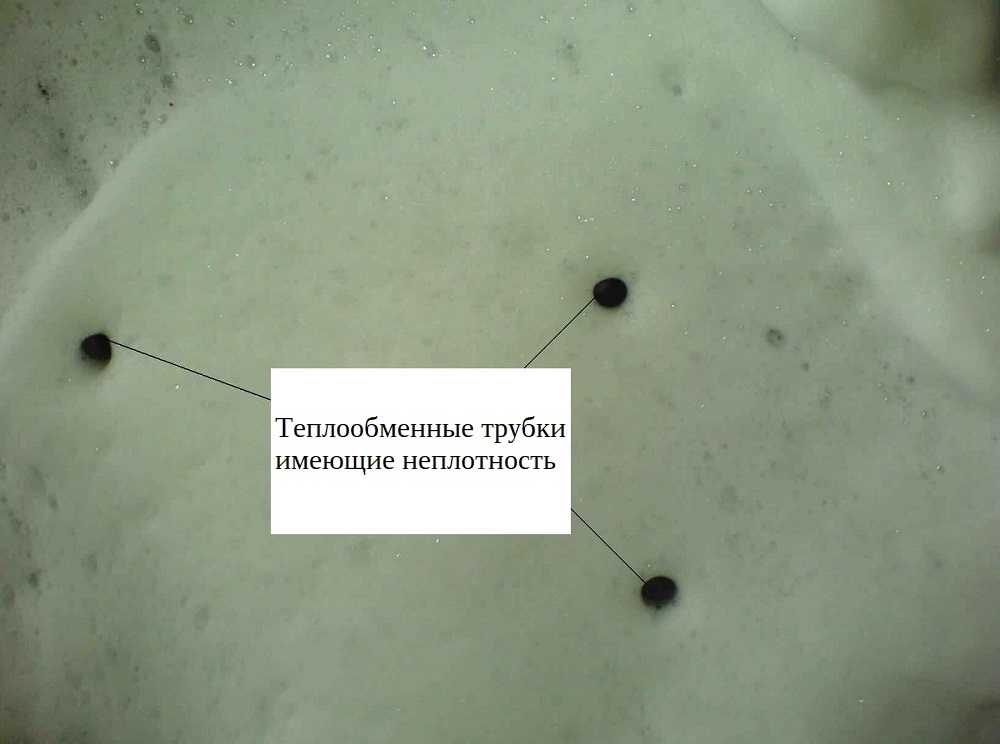

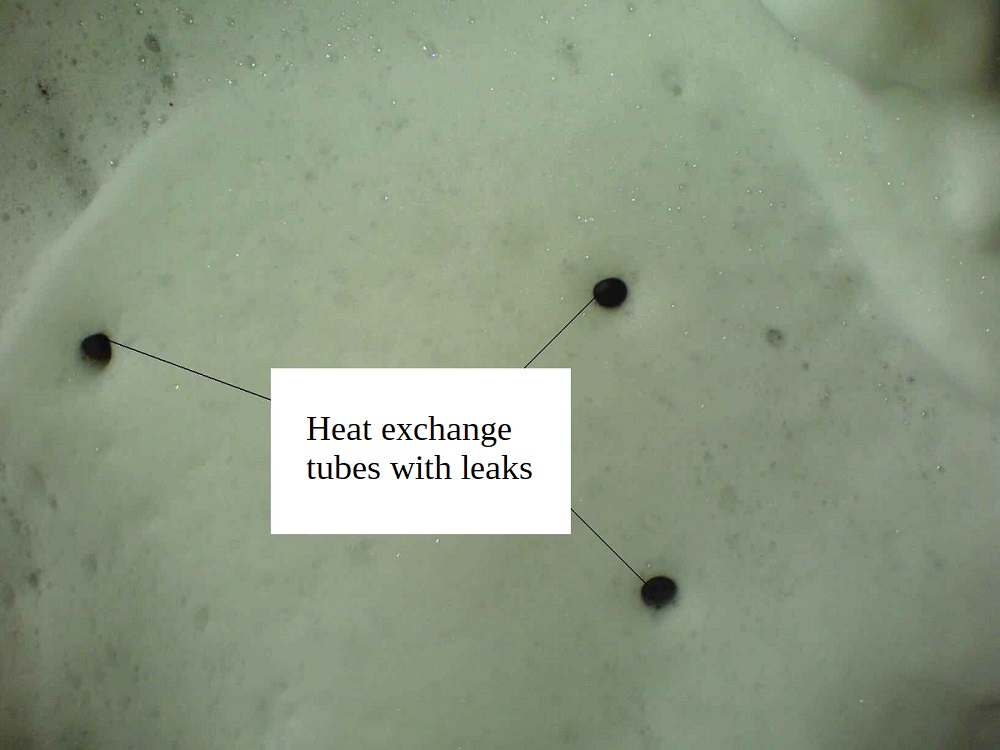

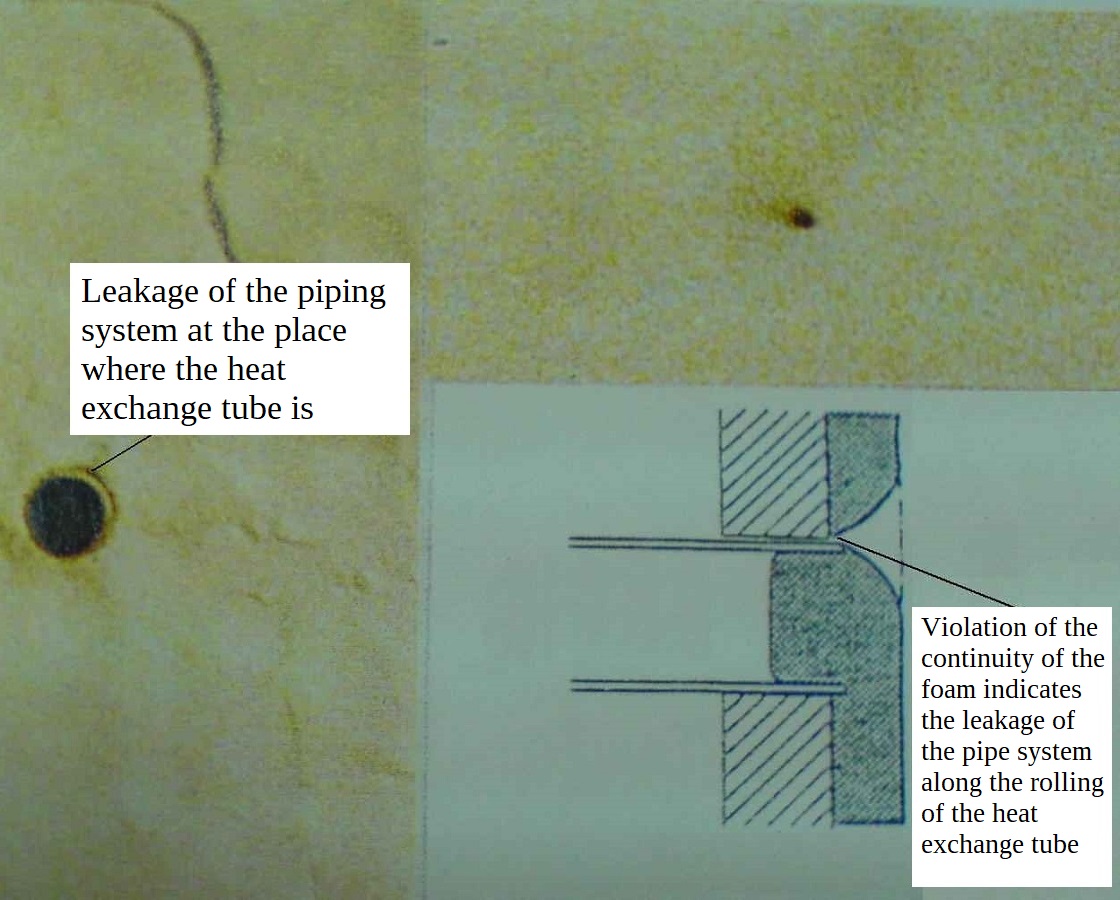

- 3. Fault detection (visual inspection) of the surface of the heat exchanger tube sheets is carried out. In the event of a violation of the continuity of the applied foam layer, the nature of the suction (leakage) of the pipe system is determined: a through defect in the wall of the heat exchange tube (Fig. 4).

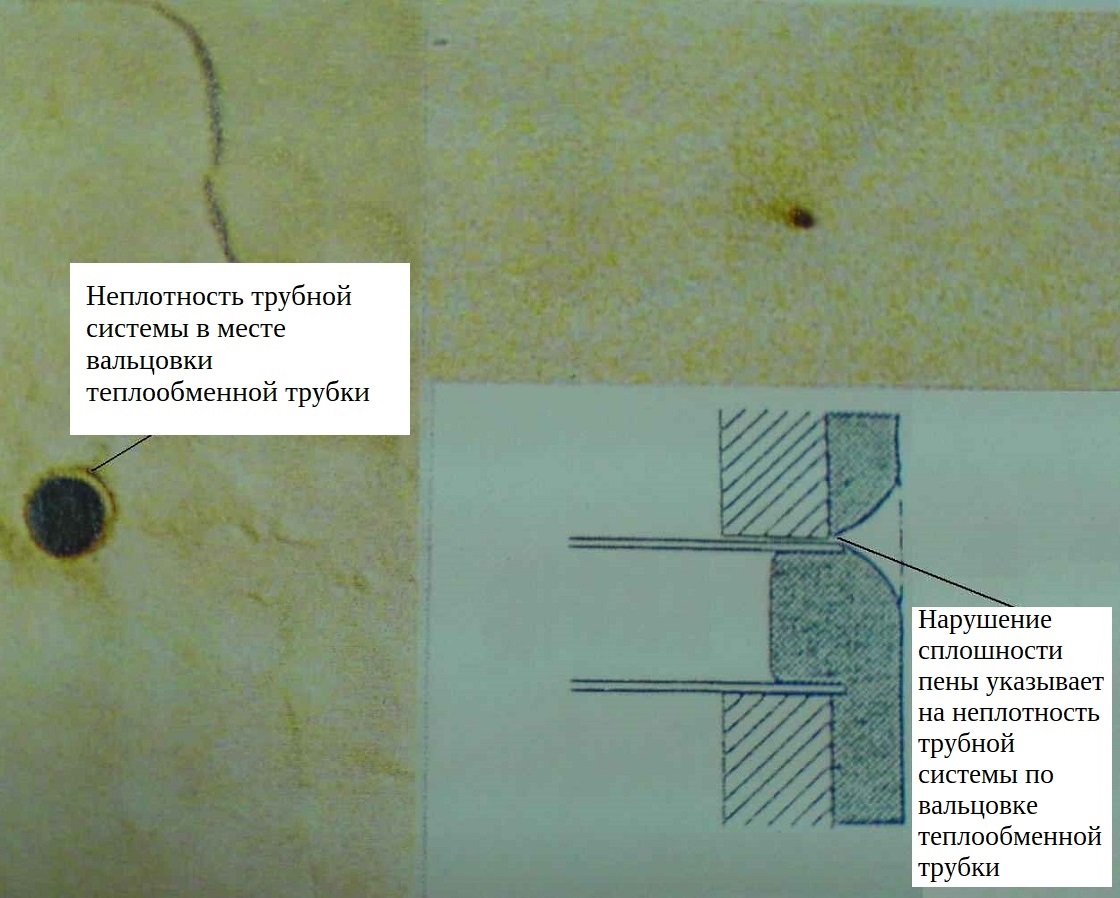

- 4. Violation of the density of the pipe system at the place of the heat exchange tube rolling (Fig. 5).

- 5. Heat exchange tubes with leaks are “jammed” with the help of special plugs.

|

Fig.1. The process of applying foam to the tube sheet of a heat exchanger. |

Fig.2. The foam is evenly applied to the heat exchanger tube sheet. |

Fig. 3 After application, the foam is smoothed over the surface of the tube sheet with spatulas. |

|

Fig.4 Heat exchange tubes are leaky. |

Fig. 5 Rolling. |

The main advantages of using the method of searching for suction cups using the FORWARD modernized foam in comparison with other methods:

- 1. Due to a significant reduction in the time of fault detection of the condenser pipe systems, the operating time of the power unit in the "reduced" power mode is reduced. Fault detection ~10000 heat exchange tubes is 45-50 minutes!

- 2. Possibility of detection of microsuckers (1,5-2 l/hour).

- 3. Accuracy of finding leaky heat exchange tubes in steam turbine condensers.

- 4. Possibility of fault detection of the rolling joint "heat-exchange tube - tube sheet".

- 5. Ease of use of the foam suction method. To perform these works, workers are not required to have special skills.